Safety Appliance Application (K1)

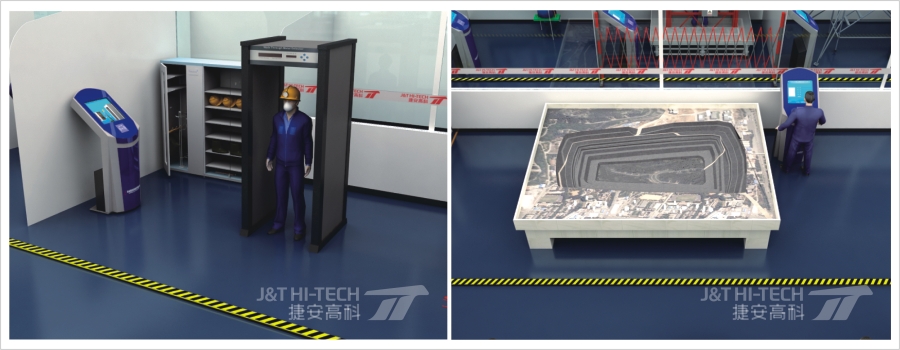

Personal Protective Article Dressing (K11)

The tester checks and selects the protective articles in the tool cabinet for dressing and the system would make judgement automatically. The personal protective article maintenance knowledge is evaluated on the test terminal.

Mine Safety Symbol Identification (K12)

The system would automatically judge the safety symbol identification and application of the tester.

Safety Operation Technology (K2)

Open Pit Slope Safety Inspection (K21)

Step Safety Inspection (K22)

This segment provides the open pit slope sand table (including various modeling) for the tester. The module is set with the test topic according to the test standard, such as pit slope, pit slope fault, landslide mass and so on. The test answers the question through the modeling observation and the system would automatically scoring.

Perforation Operation Safety Inspection (K23)

The tester clicks the corresponding article in the scenery for carrying out the following inspections: safety distance between the perforator and the step bench edge, stability of the perforator winch, personnel safety during the perforation operation and safety distance between the perforator and the equipment. Meanwhile, the system would give the corresponding test topic for evaluating the corresponding operation.

Blasting Powder Charge Operation Safety Inspection (K24)

The tester clicks the corresponding article in the scenery for carrying out the following inspections: blasting operator certification, alert measures before operation, blasting safety distance, blasting equipment, powder charge and connection operation. Meanwhile, the system would give the corresponding test topic for evaluating the corresponding operation.

Shovel Loading Operation Safety Inspection (K25)

The tester clicks the corresponding article in the scenery for carrying out the following inspections: nobody is inside the excavator operation cantilever and bucket movement area, the transportation device should not overload or the load is uneven, the huge rock should not be loaded on one-side of the car, the bucket should not pass by the cab while loading, and the car driver should not stay on the cab ladder or the rock fall area.

Road Transportation Safety Inspection (K26)

The tester clicks the corresponding article in the scenery for carrying out the following inspections: there should be alert symbol at the road sharp turn, steep slope and danger area, there should be set the stop wall outside the road at the slope area and high embankment road section, the ore discharge location should be set with the slide stop device and should be instructed by specialized staff, if the driver leaves the cab or put the head or arm out the cab during the car loading process, and so on.

Waste-dump Safety Inspection (K27)

The tester clicks the corresponding article in the scenery for carrying out the following inspections: waste-dump platform, slope, car stop and soil discharge operation.

Tailings Reservoir Safety Inspection (K28)

The system provides the scaled-down modeling which is set with the test topic according to the test standard, such as: dam body slope gully, crack, collapse pits, landslide, drainage shaft, chute, culvert, and so on. The tester observes the modeling and answers the question.

Power Supply System Safety Inspection (K29)

Operation Site Potential Safety Risk Elimination (K3)

Potential Accident Risk Rectification Procedure (K31)

This Segment contains all the test standard required operation procedure and reports according to the regulation.

For the general potential accident risk, the related responsible person or related personnel should organize and rectify.

For the significant potential accident risk, the company main director should organize and apply the potential accident risk treatment scheme.

During the potential risk treatment process, the related safety measures should be adopted to prevent the reoccurrence of the accident.

Emergency Handling of the Operation Site (K4)

Individual Manual Cardio-pulmonary Resuscitation (CPR) Operation (K41)

Fire Extinguisher Selection and Application (K42)